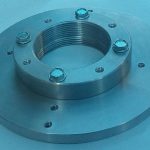

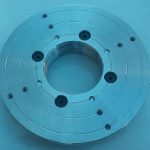

ER40 Threaded 5″ Drive Plate System

Click any image for Full Size

Check out the following Video:

Please Note that the “ER40 Rotary Table Indexer” is Not Included

The 5″ Drive Plate System can be used as is, or modified for ANY ER40 threaded nose device of your choice.

Use it for Driving/Indexing/Fixturing, or whatever your need is.

In the box:

(1) ER40 Threaded 5″ Drive Plate with pre drilled and tapped holes

(1) (3″ ER40 Threaded Drive Nut with pre drilled and tapped holes

(4) #10-24 mounting screws Flat Socket Head

(4) #10-24 mounting screws Hex Head Bolts

Instructions + the 3 B/C Diameters for the (12) pre-tapped #10-24 holes on the 5″ Drive Plate are 2 ½”, 3 ½”, and 4 ½”